Fuel Injector Service

Fuel Injector ServiceThe petrol injector valve is the only component in the entire fuel injection system that actually does the Fuel Injecting. The injector has the finest tolerance of any mechanical part of the engine. Regular servicing of fuel injectors (approx. 36000 miles) will not only maintain performance, fuel economy and minimum exhaust pollution, but will also prolong the life of very important anti-pollution components such as the Lambda sensor and catalytic converter. Both of these items are very costly to replace when they have failed.

Recognise these symptoms.

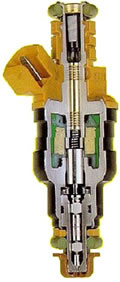

Recognise these symptoms.Problems occur when the chemicals, lacquers and varnish in various fuels, contaminate the injector. This build up can occur when the engine is switched off. “Heat soak” from the hot engine bakes the tiny amount of fuel trapped within the inactive injector, Inside the body of the injector, contamination forms on the pintle valve, the pintle head and seat and also in the filter basket. Chemical contamination and dirt in the fuel system can cause a build up inside the fine screen of the filter basket, restricting the fuel flow rate.

It has been shown that a varnish layer as fine as 5 microns on the pintle can restrict fuel flow by as much as 25%. Contamination deposits will alter the shape of the injectors spray pattern. The head of the injector pintle is ground to a specific shape, with a tolerance of up to 0.00004 of an inch. It is critical that these spray patterns are correct. Deposits on the pintle will change the shape of the spray pattern, from a fine atomised spray, to a spray that is the wrong shape, or a spray that has thin jet liquid streams, that will not burn properly. Contaminations such as these will cause driveability problems with the car.

The injector's performance is critical to the correct running of the computerised fuel injection engine. If the Air / fuel ratio should be deviated by only 1% from its pre-set limits, it could have an adverse effect upon the systems ability to control and eliminate excess pollution. This would also affect the long term performance emission control components like the lambda and catalytic converter, not to mention the money lost on wasted fuel.

The injector's performance is critical to the correct running of the computerised fuel injection engine. If the Air / fuel ratio should be deviated by only 1% from its pre-set limits, it could have an adverse effect upon the systems ability to control and eliminate excess pollution. This would also affect the long term performance emission control components like the lambda and catalytic converter, not to mention the money lost on wasted fuel.

How are they tested?

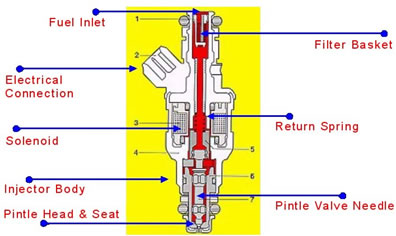

How are they tested?The injectors are removed from the engine usually there is one per cylinder unless it is a single point injection system where there is one.

They are removed because we cannot test what we cannot see!

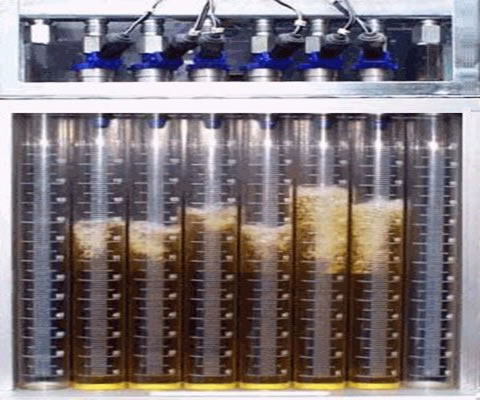

The injectors are placed in the ASNU injector test equipment and are subjected to a rigorous test to simulate a wide range of driving conditions from idle speed to full throttle and anywhere in-between. They are flow tested, spray patterns are checked for correct shape and atomisation and delivered quantity is measured in millilitres.

|

Which injector is faulty? |

Injectors are checked at different speeds and pressures to ensure Consistent results throughout the test.

Spray test shown

|

These injectors have problems with fuel atomisation only two are functioning correctly. Can you guess which ones? |

Delivered quantity is measured in millilitres

They should be equal to each other

|

As above the same injectors will give only the best delivery of fuel Can you guess which is the best? |

| Filter Baskets |

|

The injector filter baskets are removed along with the sealing “O” rings.

Injector bodies are buffed and dirt removed prior to ultrasonic cleaning.

The injectors are at this point placed in the ultrasonic cleaning tank where they are pulsed (as they are in the engine) whilst ultrasonic sound works in conjunction with the Bioclean fluid they are immersed in. The cleaning cycle takes place for up to 30 minutes to complete, at this point they are clinically clean and back to there original condition “As New”.

This injector that has been ultrasonically cleaned, it is clinically clean. Ultrasonics are used by Dentists, Doctors and Hospitals for clinically cleaning metal instruments. Ultrasonics are used successfully in industry for cleaning many objects.

This injector that has been ultrasonically cleaned, it is clinically clean. Ultrasonics are used by Dentists, Doctors and Hospitals for clinically cleaning metal instruments. Ultrasonics are used successfully in industry for cleaning many objects.

The injectors are now assembled with new parts where applicable and then refitted to the engine.

New injectors to buy are anywhere between £50 to a £150 plus vat. A typical set of 4 injectors tested and reconditioned by us can usually work out to be less than the price of one new one. * removed from the engine

This equipment is only as good as the operator. Our staff have been trained to a very high standard on both engine systems and the diagnostic equipment.

We hope this section of the website highlights the importance of injector testing, without it diagnostic procedures are incomplete and therefore faults remain unresolved.

Click for more...